Techno-polymer Vs Metal

- muhannadsawan

- Jan 30, 2024

- 3 min read

Updated: Mar 12, 2025

This week, Kite Group are looking at the benefits of using techno-polymer in place of metal for increasing warehouse safety.

Polymer and Techno-polymer?

Polymers are materials comprised of large molecules made up of repeating subunits. Polymers can be synthetic (such as polystyrene) or natural (such as proteins).

They are defined by their structure, and the characteristics associated with it, including toughness and elasticity.

A techno-polymer, on the other hand, is a polymer that has been designed to withstand extreme stress, heat, chemicals and other conditions that would cause a regular polymer to break down or deform. Read our deep dive on techno-polymer blog to find out more about the material.

Traditional Safety Products

Many safety systems mitigate risk by preventing passage into dangerous areas. These products work to physically separate areas of different risk and to protect personnel from hazards (e.g. an out-of-control vehicle, risk of electric shock).

For safety barriers, metal has been the standard material for a long time, providing a degree of shock absorption whilst remaining rigid and arresting the movement of a moving vehicle. For this reason, metal safety structures have enduring popularity for their health and safety benefits, for example crash barriers, guard rails and pedestrian barriers.

Techno-polymer in Action

As a material, techno-polymer differs from metal in several key ways. The unique polymer compound that makes up Kite’s FPS products has a much higher capacity to absorb the shock of impact. While metal systems provide a fixed, solid barrier, this can strain the floor or fixings they are attached to. Kite’s FPS techno-polymer deflects shock and returns to its original shape, significantly reducing the stress to fixings.

Techno-polymer vs Metal

There are other ways to compare the techno-polymer compound to metal. Kite’s FPS products are scratch resistant and non-corrosive, retaining a clean, sleek appearance at all times. The material is bright yellow in colour, aiding visibility and thereby reducing the likelihood of impact in the first instance – this is a clear advantage over metal. Like galvanised metal, the material is resistant to chemicals, saltwater, rust, mildew and fuel/oils. The techno-polymer is also easy to clean and holds a non-toxic food grade, making it suitable for all kinds of applications. Overall, the techno-polymer system is generally more durable, lightweight, versatile and cheaper than its metal counterpart.

Products

A few key FPS products are a must when it comes to warehouse safety.

Pedestrian Safety Barriers

To keep pedestrian areas and traffic areas separate, the Pedestrian Safety Barriers come in a range of heights and lengths to suit your workspace. A range of product options are suitable from prevent impact from light to heavy loads – check with our Sales team to find the best option for your needs.

Traffic Barriers

Available in a range of heights, the Link Traffic Barriers are suited to areas with heavy traffic. The barriers are highly modular, with the Link 150/1 being the world's first barrier with a lower rail height that can be adjusted on-site. This ensures the product can be perfectly suited to the end user’s workplace, trucks and forklifts.

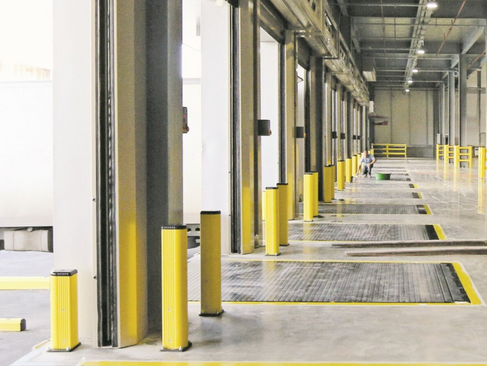

Safety Bollards

The highly visible slimline Bollards in our FPS range are a useful way to regulate traffic or pedestrian movement without blocking off an entire area. They offer excellent protection to infrastructure openings with their high impact resistance. Not only useful in warehouses, these bollards are highly suitable to protect production areas, industrial doors, overhead doors, cold storage doors, loading docks and fire doors.

Guard Rails

Our polymer Guard Rail system is designed to protect walls from impact, either at the level of trolleys, hand-pallet trucks or even forklifts. Protecting the surfaces of walls is essential to maintain a safe workplace, as well as presenting a polished interior for the benefit of employees and customers. Kite’s FPS Guard Rail system is also fully modular, adaptable to the unique layout of your building.

Follow Kite Group on LinkedIn to read about Kite’s posts and commitment to sustainability.

We offer Bespoke Service, Technical Support and Same Day Dispatch! Get in Touch today!

Comments